In LOADING IN THE YARD, the tubes to be loaded are initially stacked and grouped. The 2 operators manually load the truck, and in about 10 minutes, the truck is ready to go to the field and begin automatic distribution.

In TUBE DISTRIBUTION, with only the truck driver operating, the team previously involved in the task can be reassigned exclusively to pipeline assembly, ensuring the operation’s efficiency.

For FIELD COLLECTION, two operators group the tubes into small piles, and then the truck moves toward each pile to collect them.

Finally, UNLOADING IN THE YARD is done automatically, with the truck stationary. During this time, two operators monitor the tubes being deposited onto the yard floor.

{$description}

Agro challenges us to seek innovation daily. 🌱💡

In order to overcome the challenges and address safety needs in sugarcane fields, we developed an implement to guarantee all of this in the fertigation tube distribution process:

The Hauler! Safety, agility, efficiency and automation are just some of the advantages of this project, with an exclusive AGRICEF patent. Thus, we are raising the standard of modern agriculture! Be part of this evolution! 🚜💪

Cable Tie Distribution System: optional system that distributes cable ties according to the needs of the operation.

Automation and synchronization with the tube distribution system. The system launches two clamps for every two pipes unloaded.

The 8” tube model shares the same clamping mechanism as the 10” model. Currently, the quantity of 60 units meets the full load of 56 tubes (10” model) without additional loads. However, for the 8” model (81 tubes), an additional recharge must be carried out during distribution in the operation

Its control is carried out by the monitor located in the truck's cabin, from which it is possible to control the distribution process in an objective and easy way.

Furthermore, for greater safety, the automated system informs the monitor operator if there is any alert or problem in the distribution process.

{$resume}

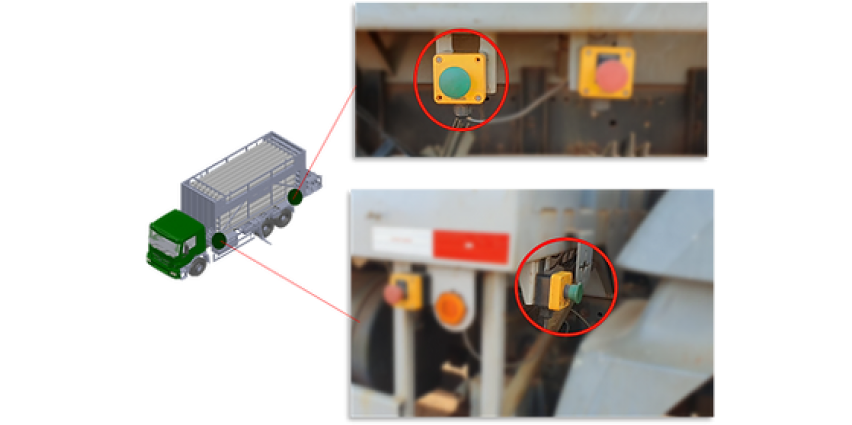

To reduce the risk of tube crushing or impacts with operators during the truck loading process, a system was developed that only allows this operation to occur when the operators are in a safe position.

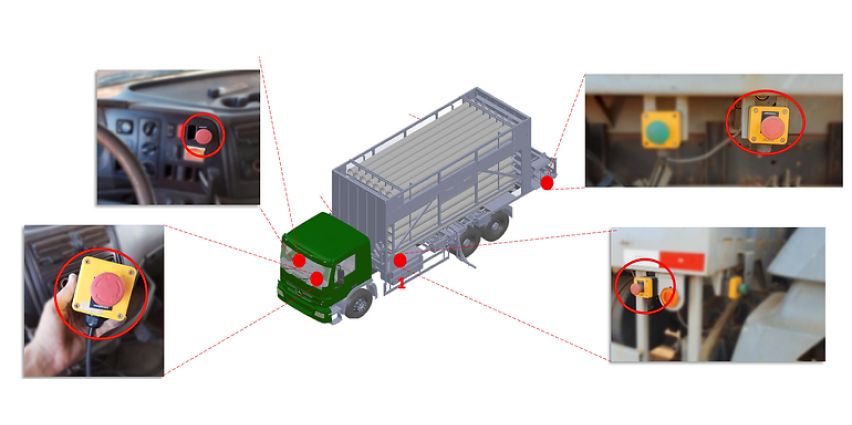

Additionally, 6 emergency buttons are available: two in the cabin and four on the sides, to be activated in any risk situation for the vehicle or operators.

{$texto_1}

{$texto_2}

| Model | 8" TUBE | 8/10" TUBE |

|---|---|---|

| Tube Diameter | 8 inches | 10 inches or 8 inches |

| MAXIMUM Tube Transport Capacity | 81 tubes | 56 tubes |

| Tube Length | 6 meters | 6 meters |

| Maximum Distribution Speed | 3km/h | 4km/h |

| Truck Specifications | 6 x 2 6 x 4 | 6 x 2 6 x 4 |

| Minimum power | 200hp for simple configuration | 200hp for simple configuration |

| Optional Items | Auxiliary Cabin Clamp Mechanism Side/Rear Auxiliary Lighting Camera Monitoring | Auxiliary Cabin Clamp Mechanism Side/Rear Auxiliary Lighting Camera Monitoring |

| '; echo $th['c']; echo ' | '; } echo '

|---|

| '; echo $td['c']; echo ' | '; } echo '

Application rate

Number of formulations

Capacidade dos reservatórios

Dimensions

Até 500 litros por hectare

Até 16 produtos diferentes

Garrafas PET com 2 litros

Altura: até 2 metros Largura: até 2,7 metros

Até 300 litros por hectare

Garrafas PET com 2 litros

Até 10 produtos diferentes

Altura: até 2 metros Largura: até 2,7 metros